Tie-Bar

Round Root

Not only use reinforced specialized material for Tie-bar; after evaluating with computer calculation, Tie-bar roots could be designed into round shape processing with CNC lathe. And this can decrease the stress concentration to up 44%, overcoming the serious broken T-shaped root problem caused by non homogenized heat treatment and overconcentrated stress on the root.

Lathe :

Primary Equipment::

1. V26-#3 / V36-#5 / V45-#7 / V46-#7 / CNC computerized lathe

2. 1000mm、3000mm、4000mm、6000mm、12000mm high speed lathe

| Aperture | ø400x6000 | CNC Computerized Lathe |

| ø230x4000 | CNC Computerized Lathe | |

| ø150x3000 | CNC Computerized Lathe |

1. V26-#3 / V36-#5 / V45-#7 / V46-#7 / CNC computerized lathe

2. 1000mm、3000mm、4000mm、6000mm、12000mm high speed lathe

Grinder

Primary Equipment: 2000mm, 3000mm, 4000mm, 6000mm, 12000mm CNC computerized barrel grinder, precision grinding QC, specialized for precision customization quality.

Miller

Primary Equipment: 1300mm, 1400mm, 1500mm, 2000mm vertical computerized miller 600, 750

horizontal CNC computerized miller.

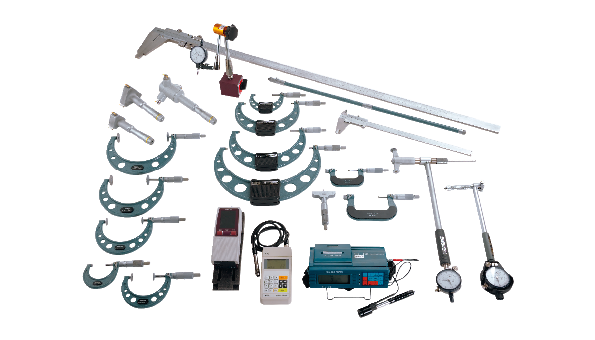

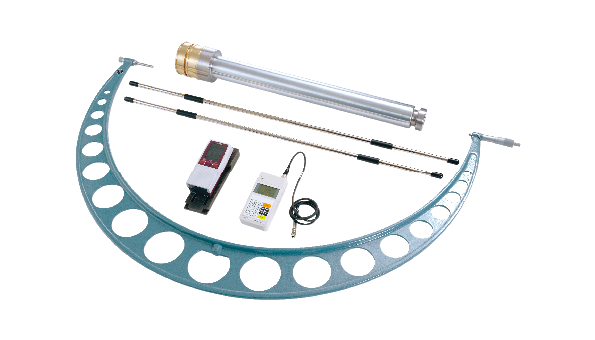

Analytic Equipment

Analytic Equipment: gauge, vernier caliper, micrometer for interior and exterior diameter, disc type micrometer, 3 wire gauge, cylinder bore gauge, depth gauge, hardness tester, coating thickness tester, surface topology interferometer, coordinate measuring machine…, etc.

Product Information

Steel material for Tie-bar, mandrel processing: JFE880NH、SCM440QT、S45CQT、SNCM439、SCM415.

Product Category

Follow Us

Contact Us

No.258-54, Anding, Ancha Vil., Anding Dist., Tainan City 745, Taiwan

Tel: +886-6-5924302

Fax: +886-6-5924334

E-mail: cl.a4302@msa.hinet.net